Let Loose the Possible of Your Workflow With Proven Walking Stick Sugar Processing Chemical Formulations

In the realm of walking cane sugar handling, the mission for operational excellence is a consistent quest - Cane Sugar Processing Chemicals. The use of tested chemical formulations has actually arised as an important aspect in optimizing manufacturing processes and elevating total effectiveness. By integrating these solutions right into your operations, a range of benefits awaits, assuring improved yields, enhanced purity levels, and streamlined procedures that line up with your tactical purposes. As the market advances, staying abreast of these improvements could be the separating aspect that drives your procedures to new elevations of success.

Enhancing Manufacturing Efficiency

To enhance manufacturing performance in cane sugar processing, it is imperative to streamline operational processes and adopt innovative technologies where appropriate. By executing effective operational procedures, such as automating manual tasks and making use of data-driven insights, sugar processing plants can considerably improve their productivity levels.

By welcoming automation and digitalization, sugar processing centers can operate with greater precision and dependability, ultimately leading to increased manufacturing output and enhanced product high quality. In significance, the quest of manufacturing efficiency via streamlined processes and cutting-edge innovations is extremely important for the sustainable development and competitiveness of walking stick sugar handling operations.

Optimizing Yields and Purity

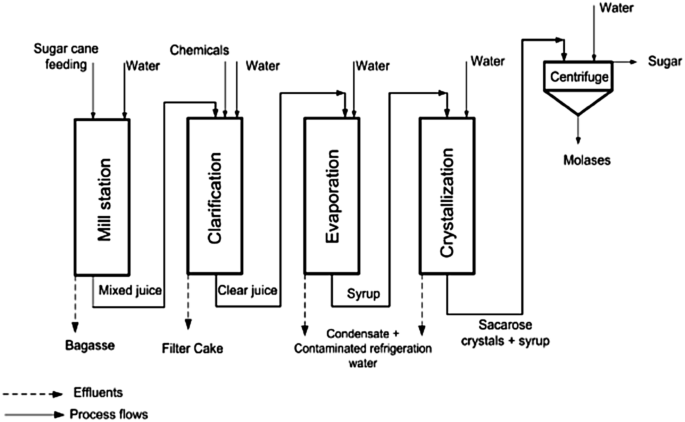

Successfully making the most of returns and maintaining high purity degrees are vital purposes in the cane sugar processing sector. Attaining optimal yields while promoting stringent purity requirements calls for a tactical technique that incorporates innovative chemical solutions into the handling operations. By employing specialized chemicals developed to improve removal performance, clarify the juice, and improve crystallization processes, sugar mills can dramatically enhance their overall yields and purity levels.

Improving Refine Optimization

In the world of walking cane sugar processing, boosting process optimization is vital for achieving the preferred returns and purity levels while incorporating advanced chemical solutions for improved effectiveness. Normal maintenance routines and thorough cleaning treatments additionally play an essential function in maintaining the handling plant running smoothly and avoiding unanticipated downtime. Welcoming procedure optimization as a core principle can lead to sustainable enhancements in performance and item quality within the walking stick sugar handling sector.

Getting Operational Goals Effectively

With a tactical focus on functional quality, the sugar handling sector aims to effectively satisfy its manufacturing targets and top quality criteria. Achieving operational goals effectively requires a combination of elements such as streamlined processes, advanced innovations, and enhanced chemical solutions. By making certain that each action of the sugar handling procedure is meticulously intended and implemented, business can improve effectiveness and efficiency.

One secret element of accomplishing operational goals is the option of top quality cane sugar processing chemical solutions. These solutions play a critical duty in different stages of the production procedure, consisting of removal, purification, and crystallization. By utilizing tried and tested chemical solutions particularly designed for cane sugar handling, firms can enhance yield, lower handling time, and enhance the total top quality of the final product.

Furthermore, effective interaction and partnership amongst different departments within the company are vital for aligning functional goals and ensuring smooth operations - Cane Sugar Processing he said Chemicals. Routine efficiency examinations, continuous training programs, and data-driven decision-making procedures can even more support the accomplishment of operational quality in the sugar handling industry. By carrying click here for more out these techniques, firms can release the complete capacity of their procedures and stay in advance in an open market

Enhancing Output Quality

Furthermore, enhancing output high quality additionally requires continual monitoring and adjustment of processing specifications to preserve uniformity and fulfill quality specifications. Quality control steps such as routine screening for pureness, dampness web content, and granulation make certain that completion item meets industry standards and customer expectations. By investing in the best chemical formulas and prioritizing quality throughout the production process, sugar processing centers can attain superior final product top quality that establishes them apart in the marketplace.

Verdict

To conclude, making use of proven walking cane sugar handling chemical solutions can significantly improve manufacturing efficiency, make the most of returns and pureness, enhance process optimization, achieve functional objectives effectively, and enhance output top quality (Cane Sugar Processing Chemicals). index By integrating these formulas into procedures, business can unlock the complete possibility of their sugar processing facilities and ensure an extra streamlined and successful manufacturing process